First thing is to get the stern up as high as possible by lowering the

jack all the way down so you don't have to stand on your head.

I've got flotation blocks in the lower outside corners of my transom, then smaller blocks the rest of the way up. MJ Thomas at

Bennett

helped me with measurements that indicated the top of the 'small'

actuators included in the M-80 kit would have been inside these flotation blocks, prohibiting me from using the clean, thru transom

hydraulics.

|

| This is how I measured. |

But the longer actuators would clear the lower block so the thru hole

for the hydraulic line can be easily accessible from the inside of the boat.

Bennett

Bennett shipped the longer actuators to me even before I received my tab kit.

The tab/hinge assemblyy is pretty straightforward -- tape the plates in

position, mark the holes and drill. The instructions say to use a 9/64"

bit, and to go to 5/32 if necessary. I'm guessing this is because a thin

fiberglass transom with wood would benefit from a better grip in the

wood with a smaller pilot. The glass in my transom needed the bigger

hole. But being perpendicularly challenged, I needed help in making sure

I didn't skew the holes as I drilled them. So as usual for me, I used

the drill press to make a hole in a square helper, then adjusted the

drill bit in the chuck to give me the required depth.

|

|

| This pilot hole is a perpendicular guide for transom drilling. |

|

|

| With this setup the hole in my transom would be just the right length for the screw. |

The helper is shown here used for the upper actuator holes.

|

| I actually used this setup for the hinge/tab first to get a perpendicular hole that is just the right depth. |

With the tab/hinge in place, I used a straight edge held against the

bottom of the boat with a bottle jack and 5/8 spacer to hold the tab up

while I positioned the actuator, then taped the template in proper

position for the upper holes. I didn't get a pic during the process, so I

re-rigged it after the installation to show how I did it. You may

notice in some places the pictures seem to get ahead of themselves -

because I wasn't real good at taking them in real sequence.

|

|

| This picture was taken after I had fastened the top of the actuator but shows how I measured. |

|

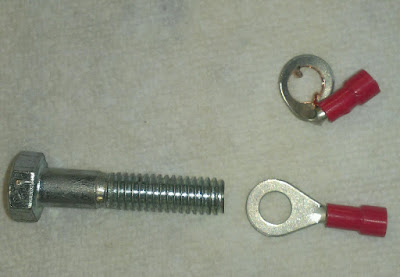

After drilling the 3/8" pilots for the the mounting fasteners, I put in

the 3/4" hole for the thru transom hydraulic line, hoping I'd

measured/calculated correctly.

And "Phew", I had!

|

You can see the hydraulic line coming thru the transom. If the hole was a

little more outward I'd have been into the flotation; and with the 2"

shorter 'small' actuator I would have been into the flotation block below.

|

I like to chamfer the pilot holes and fill them with sealant before installation. A chamfer will keep the gelcoat from cracking when the fastener is run in.

|

| Using a horse needle on the syringe I can fill the hole from the inside out. |

More on the syringe technique here.

I also like to swab the thru hull with sealant to protect the wood, and

being anxious to finish the job before the sealer set up, used a

'sleeve' to feed the hose thru to keep it from getting all gooped up.

I used the same syringe without the needle for applying sealant to the actuator.

Oh, and

Bennett even had the forethought

to tape the end of the line running thru the transom to keep junk out of

the line during installation.

They might have thought to do the same thing to the actuators while measuring and drilling; it's not a bad idea to do it yourself.

I'm always hesitant to put holes in my boat, but

Bennett has made it fun!

It's been a very satisfying morning.

Now all I have to do is notch and refit the swim platform, re-attach the anchor holder and get the inside stuff done.

BTW - if you plan to purchase the indicator for tab position, you'll want to do it right away as it would otherwise require you to remove the actuators to fit the new sender portion (and another hole in the transom). After I had my new tabs fully installed I learned of a free indicator offer - which I took advantage of and had to remove/modify/replace the actuators - in addition to the new hole for the sender wire.